Upgrade your compressor with the latest technology and components to improve your performance, energy consumption and reliability- with just an addition of our range of optimization products

Optimized performance

Upgrading your equipment to the newest standards may not only restore your compressors’ original performance, it may actually enhance it

Enhanced reliability

Years of operation in demanding conditions can take its toll on performance. A motor, element or converter exchange will make your old compressor perform like a new one

Save energy

Your compressor will be equipped with the latest available options, allowing you to make substantial energy savings

Reciprocating Compressor block replacement

Replacement of block will improve the performance of machine like a new compressor. This will increase efficiency in a cost effective manner.

- 100% Oil free air

- Balanced Opposed Design- suited right for your existing compressor

- Less vibration and pulsation- maintaining the optimum db level

- Designed as per API 618

- Long service interval, 6000 hour/year without service intervention

- Highest volumetric efficiency

Water cooled to air cooled conversion

Clean water should be provided for cooling. If the cooling water has high percentage of lime sulphur, silt, mud or other impurities will get deposited in the cylinder jackets, heads, intercooler and aftercooler tubes and shell The scale deposits unless removed will obstruct the flow of water, lower the rate of heat transfer and may result in damage to machine or reduce the life of machine. To overcome these problems, convert to Air cooled.

1.Higher overall reliability

2.Space saver- No separate space required for cooling tower and water pump

3.Energy efficient

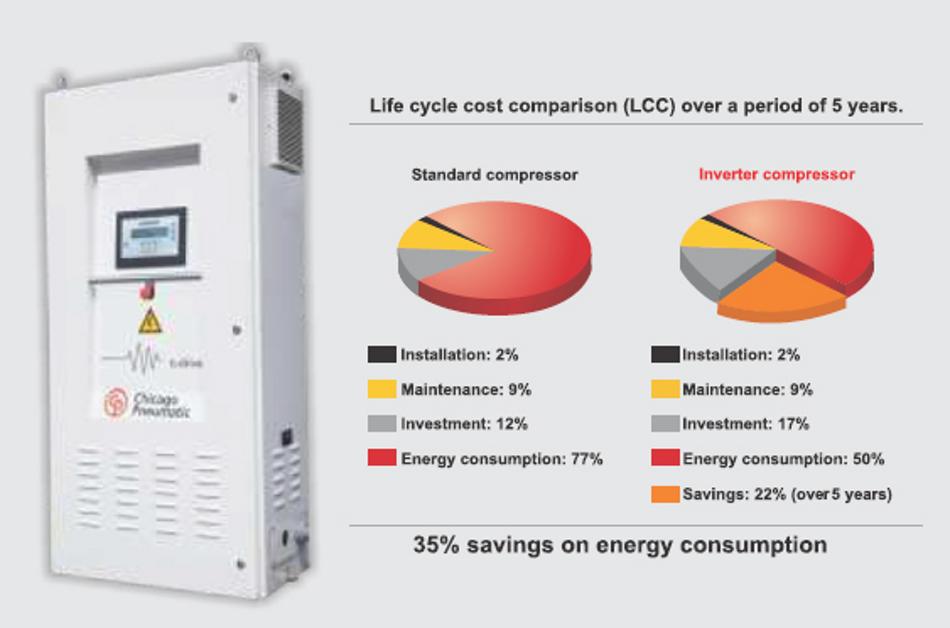

VFD Upgradation

Standardization for Reliability and Efficiency

Why should you consider a VFD kit on to your machine?

- Constant outlet pressure

- Low starting current

- A high and stable power factor

- Remote mounting

- Minimum maintenance

- High efficiency

Proven reliability throughout the world, incorporating the experience and competence of two earlier generations.

Electronic Variable Speed AC Drive -known for its advanced technology and quality.

Industry standardized VFD kit ensures fast and efficient service support on a global scale.

Energy recovery

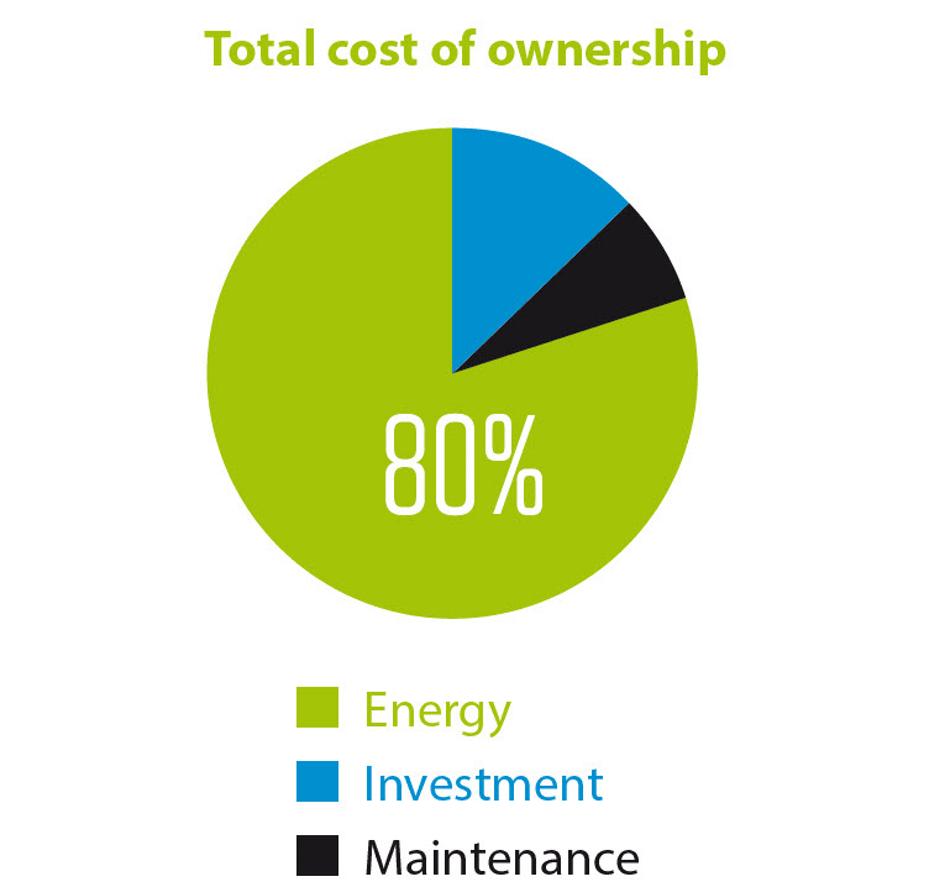

Re-use up to 80% of your compressor’s thermal energy.

Energy Box

Air compressors are big consumers of energy. In fact, over the lifetime of a compressor, energy consumption typically represents 80% of its total cost of ownership. That’s why recovering the compressor’s energy means saving money.

The way to achieve this is by harnessing the compression heat. Even the most efficient compressor transforms up to 94% of the electric energy into heat. A large part of this heat is released into the atmosphere via the compressor’s cooling system.

With the Energy Box, you can recover up to 80% of this valuable thermal energy.

Discover some of the energy saving applications of the Energy Box in different industries

- General: heating systems, showers, hot water feed

- Diaries: process boiler feed, pasteurization, drying & scalding process, sterilization

- Process: synthesis of gas, steam cracking, stripping, boiler feed

- Pharmaceuticals: temperature maintenance, drying process, sterilization, steam barriers

- Textile: dying, finishing

- And many others

Using an Energy Box in your circuit helps you in

Save money

Energy consumption is the biggest cost of air compression. That’s why recovering the compressor’s energy means saving money too

Reduce CO2 emissions

Saving energy also means reducing CO2 emissions. This is not just beneficial for future generations; it may help you achieve environmental targets and comply with legislation or certification.

Lower investment costs

The Energy Box delivers heat for hot water applications or industrial processes, reducing your overall investment costs

How does energy recovery work in a compressor network?

Central Controllers - eControl6

Synchronize the operation of your compressor room's multiple installations with our smart eControl6

eControl6

Get your compressed air equipment in sync

Did you know, A 1 bar pressure reduction leads to 7% ENERGY SAVING AND 15% LESS LEAKAGE

Depending on the installation, control requirements and the number of compressors that need to be managed centrally, CP now offers LEADAIR with a range of master controls tailored to your needs. To best answer instant demand, optimizing the operation of multiple compressors with different flows and technologies is a requirement.LEADAIR continuously measures network pressure and uses the best suited equipment to cover the required demand, taking into account technical parameters and possible savings.

When is it time to install eControl6?

Energy cost savings

Lowers energy consumption by reducing long periods of unloaded operation. ECOntrol will control up to 6 compressors

User-Designed Operation

Control the entire network from a single point with Clear graphic display Online monitoring and control available

Complete Control of compressor room

Visual overview of compressor room along with Equalization of running hours, spread over different compressors with similar priorities

Intelligent solution

Production fluctuations and the use of different pressure profiles demand for an intelligent solution which manages all centrally

Savings through Harmony and Control

The ECOntrol6 gives you a well-managed compressed air system that decreases downtime and maintenance, while increasing production and most importantly, lowering your energy costs. Chicago Pneumatic Multilogic Controllers give you a single point of control, which allows you to more efficiently monitor and regulate multiple compressors (branded and non-branded) simultaneously. Troubleshooting becomes much easier as the system will recognize problems immediately; identifying which compressor is malfunctioning and even identifying the nature of the problem. But the most important benefit you’ll gain is better overall network performance that helps you minimize energy costs.

What's in it for you after installing eControl6?

Reduce significant total energy usage

Unload operation can represent up to 30% of the total energy usage. By controlling efficiently compressors’ priority and network pressure, energy waste can be avoided.

Reduce system pressure band

eControl6 will control all compressors within one small pressure band regardless of the air demand. This will result in significant energy saving, by programming the pressure in function of the days and hours, the right pressure can be assigned

Equal Running Time

Designed for installations where compressors’ capacities are identical, eControl6 offers an equal number of load hours on each compressor, while respecting priority classes

Timer Rotation

Using a classic and simple method, the system operates rotation of compressors based on their priority class and at regular intervals